Hangzhou, China – On January 10, the highly anticipated 2024 China Five Constants Conference was held in Hangzhou. Mastair, as the title sponsor of the event, advocated for industry peers to actively participate in implementing the Five Constants Standards. These standards encompass the constant temperature, humidity, oxygen levels, cleanliness, and quiet, with the addition of “Make Green” to promote carbon neutrality and contribute towards sustainable development, ensuring that energy consumption per 100 square meters remains below or equal to 900 kWh of electricity consumption.

The opening ceremony of the conference saw Mr. Chen Linan, CEO of Mastair Group, acknowledge the significance of the China Five Constants Conference, stating that it symbolizes the industry’s path towards rapid development. Explaining the concept of the Five Constants, “We need to express ourselves scientifically, with evidence and logic,” Mr. Chen Linan emphasized. The Five Constants represent a unique challenge proposed by integrated service providers, presenting an opportunity for “China-centric” air conditioning to overtake competitors. Technological innovation, he added, held immense commercial potential.

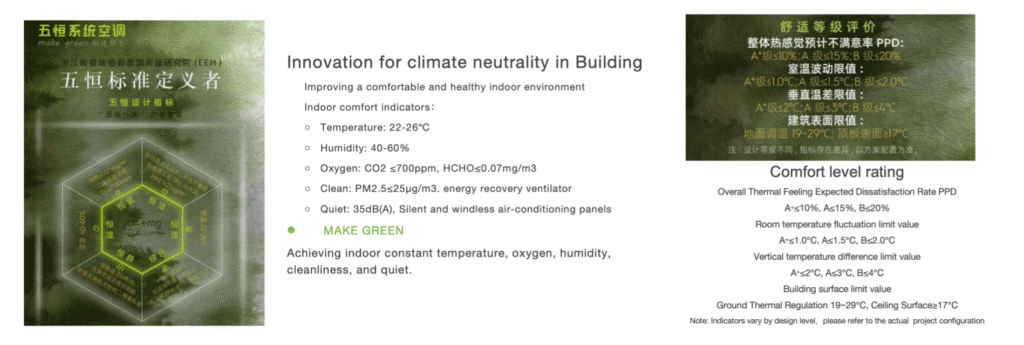

During the event, Mr. Chen Linan shared a report titled “The New system of Air Conditioning Theory–Five Constants Standards Definer,” shedding light on the subject. With a full house of 1800 attendees, the conference proved to be a resounding success.

The China Five Constants Conference stands as a significant step towards reshaping the HVAC industry and advancing towards a greener and more sustainable future.